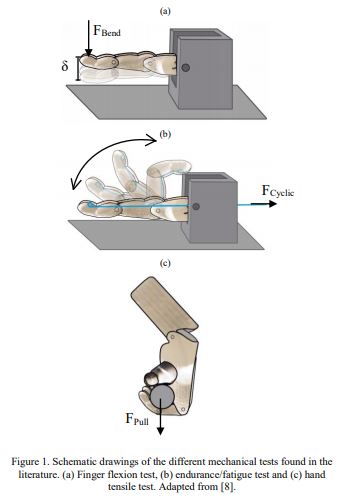

Resumen: 3D-printing technologies have greatly influenced the field of fabrication of medical devices. In particular, Fused Deposition Modeling 3D printing has emerged as one the most popular and most promising technologies for fabricating upper-limb prostheses. Over the last years, a variety of types and designs of 3D-printed hand prostheses have been created and are commercially available. However, there are no standards or established procedures for testing these devices. Available information regarding their long-term performance and functionality is very limited. This paper presents a case study of mechanical testing methods applied to a specific design of an upper-limb prosthesis. The device and its subassemblies were subjected to flexion test in hyperextension and abduction conditions, fatigue/wear test, and tensile test. The experimental results are presented and examined. Testing procedures, adaptations and recommendations are described and discussed to demonstrate ways of generating reliable data that serve for comparison among different hand prostheses designs.

Autor(es):Mio, R.; Sánchez, M.; Valverde, Q.; Lara, J. y Rumiche, F.

Año: 2019

Título de la revista: Advances in Science, Technology and Engineering Systems Journal

Volumen: 4

Número: 5

Página inicial - Página final: 61-68

ISSN: 2415-6698

Url: https://astesj.com/v04/i05/p08/